Building Pressure Control in HVAC Systems

HCE provides engineering solutions for managing building pressure through strategic zoning, air balance, and system controls. We ensure building pressurisation strategies support comfort, IAQ, and smoke control, while remaining compliant with AS/NZS 1668 and commissioning best practices.

Building pressure control is a critical component of HVAC design and operation, ensuring that air movement between spaces supports occupant health, system performance, and compliance with building codes. Managing differential pressures between zones or between indoor and outdoor environments is especially vital in buildings such as hospitals, laboratories, commercial kitchens, and high-rise residential towers.

The aim of pressure control is to maintain a consistent and intended air pressure relationship — either positive, neutral, or negative — between adjoining areas. This is achieved through precise ventilation system design, control of airflows, and integration with building management systems (BMS). Compliance with standards such as AS 1668.2, ASHRAE 62.1, and NCC Volume One – Section F & J is essential to ensure that pressure relationships are safe, effective, and energy efficient.

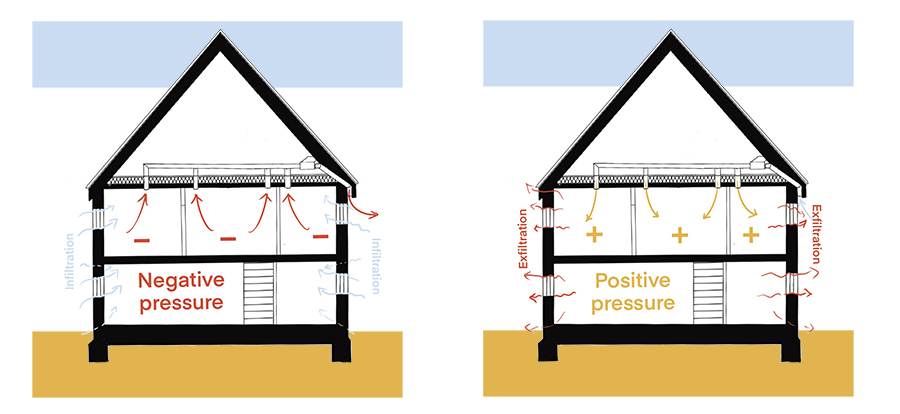

Positive and Negative Pressure Zoning

Different zones within a building require specific pressure relationships to control contaminants, odours, moisture, or thermal transfer:

Positive pressure is used to prevent the ingress of unfiltered air into a clean or controlled space. Applications include hospital operating theatres, pharmaceutical cleanrooms, and server rooms.

Negative pressure is used to contain airborne contaminants within a space and prevent their escape. Common areas include isolation rooms, laboratories, bathrooms, and waste storage zones.

To maintain these relationships:

- Sealing and door sweeps are critical to ensure actual pressure differentials are maintained under real-world conditions.

- Supply and exhaust airflows must be carefully balanced. A net positive pressure requires supply air to exceed exhaust/relief air, while a net negative pressure does the opposite.

- Airlocks and vestibules are often incorporated to buffer pressure differentials and reduce uncontrolled air leakage during door operation.

Control Strategies and Instrumentation

Accurate pressure control relies on active monitoring and responsive control logic. This typically involves:

- Differential pressure sensors across zones, which provide real-time pressure readings to the BMS

- VAV (Variable Air Volume) terminal boxes and modulating dampers to dynamically adjust supply and exhaust flows

- Door position sensors to reduce supply/exhaust response lag during access events

- PID control loops programmed within the BMS to maintain setpoint differential pressures (e.g., +5 Pa in operating rooms, -10 Pa in isolation rooms)

In high-risk facilities, redundancy is built in with dual fans, standby dampers, and alarm systems triggered when pressure relationships fall outside of allowable ranges.

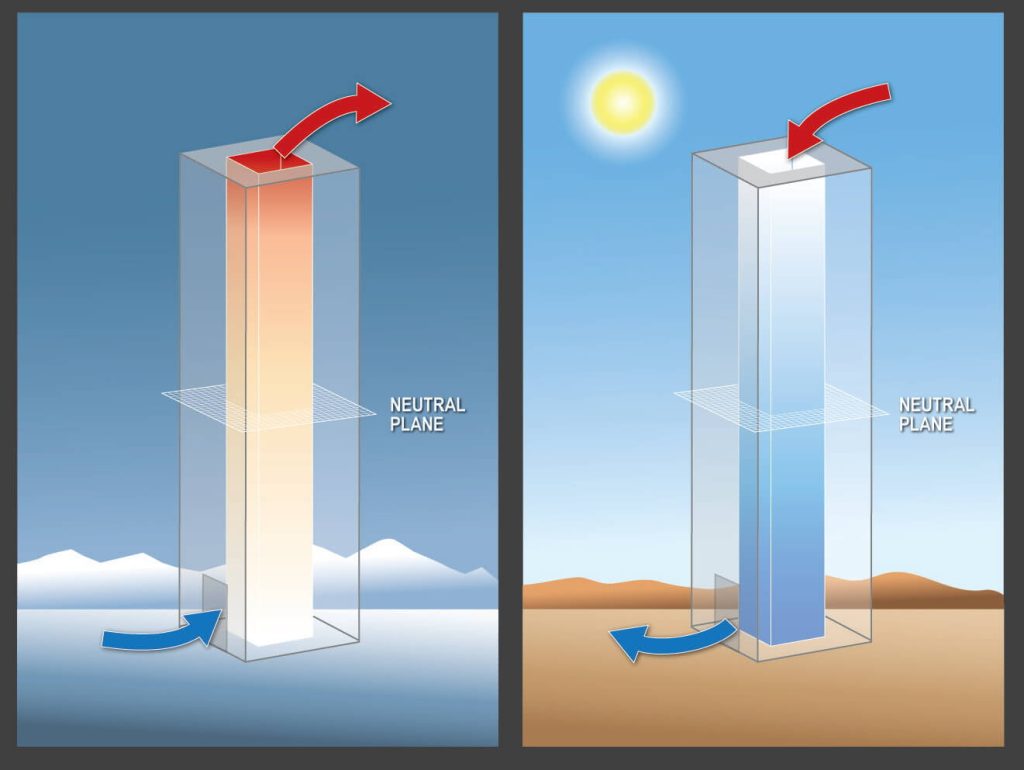

Stack Effect and Building Envelope Impacts

In multistorey buildings, stack effect—the vertical movement of air due to temperature differentials between indoors and outdoors—can significantly disrupt pressure control strategies. Cold weather can draw air in at lower levels and exhaust it at higher ones, while the reverse occurs in warm climates.

Design strategies to mitigate stack effect include:

- Zoning the building vertically with separate mechanical systems

- Using pressure relief dampers or barometric dampers to stabilise pressure fluctuations

- Maintaining airtight building envelopes, particularly in elevator shafts, stairwells, and riser ducts

A blower door test or pressure test may be required for certain building types under NCC Section J airtightness verification provisions.

Fire and Smoke Integration

Pressure control systems must also integrate with fire and smoke management systems. For example:

- Relief vents or motorised dampers must open to prevent over-pressurisation in case of mechanical failure or backflow

- Stair pressurisation systems are designed to maintain positive pressure (>50 Pa static) during fire mode, per AS 1668.1, preventing smoke ingress

- Zone pressurisation is used to compartmentalise buildings into smoke zones during fire events

Commissioning and Testing

Verifying pressure control systems involves both static and dynamic testing, including:

- Measuring differential pressure using manometers or micromanometers

- Verifying airflow rates and pressure gradients under normal and emergency conditions

- Testing door opening forces (should not exceed 110N under NCC) to ensure pressure differentials do not obstruct egress

All testing should be documented and referenced against design specifications, commissioning plans, and NCC performance requirements.