Building Management Systems (BMS)

HCE provides comprehensive control system documentation and coordination for BMS interfaces, ensuring HVAC systems operate efficiently and reliably. Our work includes controls schematics, I/O schedules, and sequence of operations for all levels of complexity, from standalone units to integrated central plant.

Building Management Systems (BMS), also referred to as Building Automation Systems (BAS), are integral to the operation and optimisation of modern HVAC systems. A well-designed BMS ensures that all mechanical services are operated efficiently, reliably, and in accordance with the building’s thermal and ventilation requirements. In HVAC applications, the BMS acts as the central control platform for air handling units, chillers, boilers, pumps, terminal units, dampers, actuators, and sensors. Its functions extend beyond basic on/off scheduling to include advanced control logic, fault detection, alarm management, trending, energy monitoring, and performance optimisation.

Australian and international standards such as ISO 16484, BACnet (ISO 16484-5), ASHRAE Guideline 13, and NCC Section J5.8 guide the design, integration, and commissioning of BMS systems. The integration of HVAC controls into a centralised BMS is increasingly important in achieving high NABERS, Green Star, and WELL Building ratings.

System Architecture and Communication Protocols

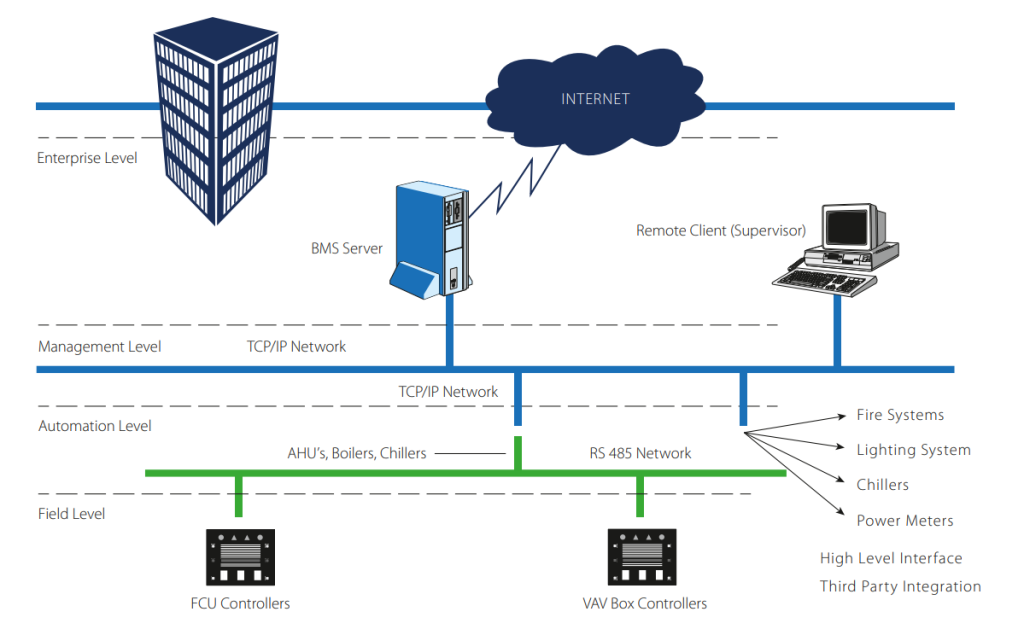

BMS architecture typically follows a hierarchical structure consisting of:

- Supervisory Controllers or front-end workstations with user interfaces (UI) for building managers.

- Field Controllers (DDC – Direct Digital Control units) for equipment such as AHUs, chillers, or VAV boxes.

- Input/Output (I/O) Modules connected to physical sensors and actuators.

These components communicate via open protocols like BACnet, Modbus, or KNX, which enable interoperability between devices from different manufacturers. Network design must address bandwidth, latency, device addressing, and cybersecurity. Most systems also include gateway devices to connect legacy or proprietary equipment.

The BMS interface allows for scheduling, real-time monitoring, trending, and remote access via secure web-based platforms or cloud-integrated solutions. Increasingly, IoT-enabled smart sensors are being used for granular control and detailed diagnostics.

Control Strategies for Energy Efficiency

Effective control strategies are critical in minimising HVAC energy consumption while maintaining occupant comfort and indoor air quality. Some core control functions include:

- Chiller and Boiler Sequencing: The BMS manages multi-unit plant to stage on/off and modulate units based on load, run-hours, and efficiency. For example, a lead-lag control algorithm ensures equitable usage across redundant chillers.

- Time Scheduling: HVAC equipment operates in alignment with building occupancy, reducing unnecessary runtime.

- Setpoint Reset: Supply air temperature, chilled water temperature, and static pressure are adjusted dynamically based on zone demand or ambient conditions. For instance, chilled water temperature may reset from 6°C to 9°C during part-load conditions, improving chiller efficiency.

- Demand-Controlled Ventilation (DCV): CO₂ sensors modulate outdoor air intake based on occupancy, reducing ventilation load when spaces are unoccupied.

- Economy Mode (Free Cooling): The BMS enables outside air dampers to open during suitable ambient conditions (e.g., OAT < indoor setpoint) to reduce mechanical cooling demand.

- Static Pressure Reset: Fan speeds are controlled using VSDs (Variable Speed Drives) to maintain minimum static pressure at the most demanding VAV terminal. Pressure sensors are placed at strategic locations to avoid over-pressurisation and wasted energy.

Zone and Terminal Unit Control

At the zone level, BMS controls terminal units such as:

- VAV boxes: Modulate airflow based on zone temperature feedback.

- Fan coil units: Use 2- or 4-pipe systems to provide local cooling/heating.

- Radiant systems: Control water temperature and flow based on room temperature and slab response time.

Each zone includes temperature sensors and, in some cases, CO₂ and humidity sensors. The BMS interprets this feedback to fine-tune supply air temperature, volume, or heating valve position. Occupancy sensors can also override schedules, allowing dynamic control in conference rooms or intermittently used spaces.

Integration with Other Building Services

An advanced BMS integrates not just HVAC, but also:

- Lighting systems (e.g., daylight harvesting and occupancy-based dimming)

- Access control and security

- Fire alarm interface (e.g., smoke extraction mode, AHU shutdown on alarm)

- Energy metering and power monitoring

- Water systems, including condenser water, hot water, and rainwater reuse

Cross-system integration supports load shedding, fault correlation, and optimisation strategies such as predictive pre-conditioning of spaces.

Monitoring, Alarming and Fault Detection

The BMS continuously monitors equipment status, environmental conditions, and energy use. Key functions include:

- Alarm Management: High/low temperature, humidity, or pressure deviations; equipment failures; communication loss.

- Trend Logging: Storage of time-series data for temperature, flow, occupancy, energy use — used for diagnostics and compliance.

- Fault Detection and Diagnostics (FDD): Rule-based or AI-driven algorithms that identify anomalies such as stuck dampers, sensor drift, or simultaneous heating and cooling.

Real-time dashboards allow facility managers to visualise system health, while analytics platforms provide benchmarking and actionable recommendations.

Commissioning and Control System Validation

Proper commissioning of the BMS is essential to ensure that controls function as designed. This includes:

- Functional Performance Testing (FPT): Verification of control sequences under all modes of operation.

- Point-to-Point Checks: Ensuring sensors, actuators, and control points respond correctly and are mapped accurately in the BMS database.

- Graphics Review: Ensuring user interfaces accurately reflect real-time status and controls.

- Trend Review: Verifying that trend logs capture key parameters at appropriate intervals.

Ongoing recommissioning or continuous commissioning programs can maintain optimal performance over time, addressing drift, occupancy changes, or operational errors.